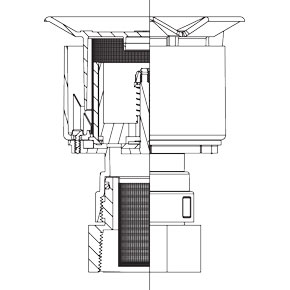

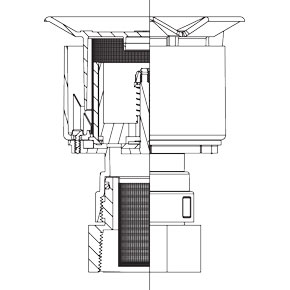

Pressure Vacuum Vents are installed on the top of vent pipes from underground or aboveground fuel storage tanks. The vent cap and internal wire screen are designed to protect the tank vent lines against intrusion and blockage from water, debris or insects. A normally closed poppet in the valve opens at a predetermined pressure or vacuum setting to allow the tank to vent.

Features

- Pressure/Vacuum Setting – 2.5" to 6" water column pressure settings and -6" to -10" water column vacuum settings are factory preset and tested.

- Reliable Service – Cycle tested to the equivalent of 80 years of service in the most severe environment without leakage problems.

- Corrosion-Resistant Construction – A Duratuff® composite body assures a long service life.

- Easy Installation – The 623V is available in 2" and 3" threaded versions.

- Complies with NFPA 30 Requirements – for venting gasoline vapors upward.

- Manifold Vent Pipes – Vent pipes may be manifolded to produce a single Pressure Vacuum Vent line. The 623V exceeds California's requirements of a maximum vapor leak rate of 0.17 SCFH at 2.00 inches H2O.

- High Maximum Flow Rate – 6450 SCFH at 2 psi (0.1 bar) pressure drop.

- Leak Rate – Multiple pressure vacuum vents may be installed on a single site. The 623V exceeds California standards with a leak rate of 0.05 SCFH or less at 2.00 inches H2O.

- Maintenance – No tools required. A removable snap fit top allows for easy maintenance (recommended yearly).

- 100-Mesh Stainless Steel Wire Screens – Helps prevent debris and insects from entering the tank vent lines. An added screen installed at the base prevents debris from intruding from the vent stack.

- Adaptor Bushing – Removable Hex threaded bushing designed for easy installation on NPT threaded risers. Allows easy access to lower screen.

- ATEX Approved – For flame arrestor applications.

Materials

- Top/Body: polypropylene

- Base: anodized aluminum

- Poppet: anodized aluminum

- Screen: stainless steel mesh

- Gasket: closed cell foam

Patent No. WO2004/036096AZ

Ordering Specifications

| Product # |

Description |

Identification Label Color |

lb. |

kg |

| 623V-2203 |

2.5" to 6" WC Pres., -6" to -10" WC Vac. Thread-On |

Yellow |

1.55 |

.70 |

| 623V-3203 |

2.5" to 6" WC Pres., -6" to -10" WC Vac. Thread-On |

Yellow |

2.20 |

1.00 |

Conversion Table

| Measurement Units |

= |

Oz. |

PSI |

PSI (WC) |

(Merc) |

Bar |

| Bar |

x |

236.0 |

14.5 |

401.4 |

29.53 |

|

| In. Hg (Mercury) |

x |

7.843 |

0.49 |

13.6 |

|

0.034 |

| In H2O (WC) |

x |

0.578 |

0.04 |

|

0.074 |

0.002 |

| PSI |

x |

16.00 |

|

27.68 |

2.04 |

0.069 |

| Oz. |

x |

|

0.063 |

1.73 |

0.128 |

0.004 |

Replacement Parts

| Part Number |

Description |

| C05086M |

Lower Screen |

| H14895M |

Upper Screen |

| C05089 |

2" Threaded Base Adaptor |

| C05122 |

3" Threaded Base Adaptor |

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED