- Description

Model Descriptions

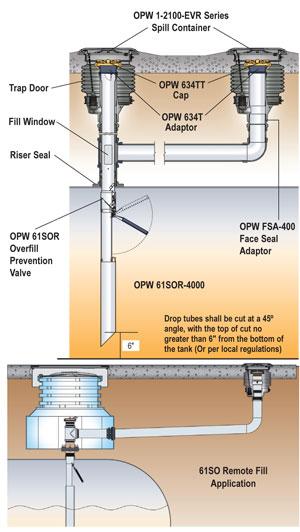

61SOR Remote-Fill

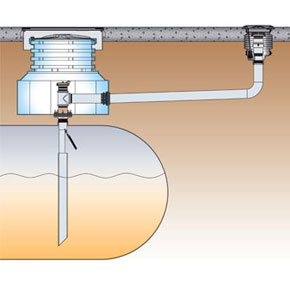

The OPW 61SOR is designed for two-point remote-fill applications, where the fill point is not directly over the UST. The valve is installed in the tank through a riser pipe directly over the tank. A window in the drop tube is aligned with the entrance of the fill pipe from the remote-fill location to allow product to flow into the drop tube and down through the valve. A riser seal prevents product from flowing into the tank from outside the drop tube. A “trap door” assembly installed in the riser above the tank provides access for a gauging stick. Trap door, adaptor and cap are included with 61SOR.

61SOR Remote Fill Tube Instruction Sheet Order Number: H11964M

61SOC Coaxial

The OPW 61SOC is used for coaxial fill applications, tanks equipped with a single product/vapor return connection. The 61SOC replaces the standard coaxial fill drop tube in a 4" riser fill pipe.

61SO-4000 Series Instruction Sheet Order Number: H11764M

61SOC Coaxial Fill Tube Instruction Sheet Order Number: C03634PA

Features

- Simple, Easy, Quick Installation - No excavation or special manholes required.

- Economical - Costs a fraction of expensive, complicated and difficult to install valves.

- Furnished Complete - Supplied with new upper and lower drop tubes, mounting hardware and thorough instructions for a quick job site time.

- Completely Automatic Operation - No pre-checks to perform, no resets, and no overrides to be broken or abused.

- No Pressurization of the Tank - Operates directly from liquid level.

- Will Accept a Dipstick for Gauging.

- Retrofits Directly - For both new and existing tanks with 3" or 4" fill risers.

- Quick Drain Feature - Automatically drains hose when head pressure is relieved.

- Best Flow Rate in The Industry.*

*Test-witnessed by Bowser-Morner, Inc., an independent laboratory. Results available upon request.

Advantages of Overfill Prevention Compared to Overfill Warning System

- Completely Automatic Operation - Does not rely on the alertness or speed of response of the delivery attendant for certainty of overfill prevention.

- Keeps the Top of UST “Dry,” per EPA Requirements - Eliminating possible leaks at loose bung fittings and the need for double containment on vent lines.

- Does Not Rely on Pressure in the UST to Stop Flow - Allowing faster fill times and reducing spill risk.

- Speeds Delivery Operations - Product flows unimpeded into the tank until the hose “kick” that accompanies the valve shut-off provides a clear signal that the liquid has reached the shut-off level.

- Simple and Inexpensive Installation - In both two-point and coaxial fill applications, no additional excavation, manholes or vent piping are required.

Additional Features

The OPW 61SO is a two-stage shut-off valve. When the liquid level rises to about 95% of tank capacity, the valve mechanism is released, closing automatically with the flow. This reduces the flow rate to approximately 5 gpm through a bypass valve. The operator may then stop the filling process and disconnect and drain the delivery hose. As long as the liquid exceeds the 95% level, the valve will close automatically each time delivery is attempted. If the delivery is not stopped and the liquid rises to about 98% of tank capacity, the bypass valve closes completely. No additional liquid can flow into the tank until the level drops below a reset point. Models of the 61SO are available to meet virtually any UST application including two-point, coaxial, poppeted coaxial and remote fill. Methanol approved models are also available. The OPW 61SO is approved by the New York City Fire Department. (Approval #4902).Materials

- Valve body: Cast aluminum

- Float: Nitrile rubber, closed cell foam

- Valve: Aluminum

- Seals: Viton®

- Upper & lower Drop Tube: Aluminum

- Plastic parts: Acetal

- Hardware: Stainless steel

71SO Vapor-Tight Remote Fill

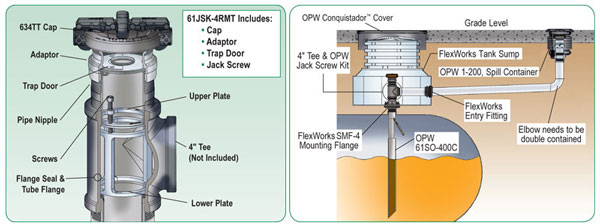

The OPW Vapor-Tight Remote Fill is designed for two-point vapor-tight remote-fill applications, where the fill point is not directly over the UST. A CARB approved vapor-tight 61SO overfill valve is installed in the sump through a riser pipe directly over the tank. The 61JSK-4RMT Kit installed within a 4” Tee provides an anchoring mechanism by locking the 61SO overfill valve in the tank fill riser. The “trap-door” assembly installed in the riser above the tank retains access for a gauge stick. The 61JSK-4RMT Kit coupled with any Vapor-Tight 61SO Overfill Valve will work for this application.

Listings & Certifications

Listings and Certifications

New York City Fire Department (Approval #4902)

Notes and Warnings

In order to prevent product spillage from the Underground Storage Tank (UST), properly maintained delivery equipment and a proper connection at the tight-fill adaptor are essential. Delivery personnel should be managed and trained to inspect delivery elbows and hoses for damaged and missing parts. They should always make certain there is a positive connection between the adaptor and elbow. If delivery equipment is not properly maintained, or the elbow is not securely coupled to the adaptor, a serious spill may result when the OPW 61SO closes, causing a hazard and environmental contamination. NOTE: The OPW 61SO is designed for use on tight-fill gravity drop applications only. Do not use for pressure fill applications.

Ordering Specifications

| Product/Suffix Number | Description | A-Upper Tube Length | B-Lower Tube Length | C-Overall Length. | Max. Riser Length | Max. Nominal Tank Dia. | Max. Actual Tank Dia. | Weight | |||||||

| in. | m | in. | m | in. | m | in. | m | in. | m | in. | m | lbs. | kg | ||

| 61SOM-412C-EVR*‡ | CARB 4", two-point, ethanol/methanol | 120 | 3.1 | not included | 233-3/8 | 5.9 | 113-1/2 | 2.9 | 120 | 3.1 | 126 | 3.2 | 25 | 11 | |

| 61SOC-4001 | Coaxial | 60 | 1.5 | 83 | 2.1 | 154-3/8 | 3.9 | 53-1/2 | 1.4 | 96 | 2.4 | 107 | 2.7 | 16 | 7 |

| 61SOC-4011 | Coaxial | 120 | 3.1 | 102 | 2.6 | 233-3/8 | 5.9 | 113-1/2 | 2.9 | 120 | 3.1 | 126 | 3.2 | 25 | 11 |

| 61SOP-4002 | CARB, pop. coaxial | 60 | 1.5 | 83 | 2.1 | 154-3/8 | 3.9 | 53-1/2 | 1.4 | 96 | 2.4 | 107 | 2.7 | 20 | 9 |

| 61SOP-4012 | CARB, pop. coaxial | 108 | 207 | 102 | 2.6 | 221-3/8 | 5.9 | 101-1/2 | 2.6 | 120 | 3.1 | 126 | 3.2 | 27 | 12 |

| 61SOR-4000** | Remote | 72 | 1.8 | 83 | 2.1 | 166-3/8 | 4.2 | 65-1/2 | 1.7 | 96 | 2.4 | 107 | 2.7 | 19 | 9 |

*For use with M85 & M100 methanol fuels. **Remote fill applications.

‡ Methanol (M85) and Ethanol (E85) models do not include lower drop tube. Adaptor for 3" A.O. Smith Fiberglass Pipe (Drop Tube) is included. Appropriate length of 3" A.O. Smith Fiberglass Pipe is required for lower Drop Tube (not furnished).

Dimensions

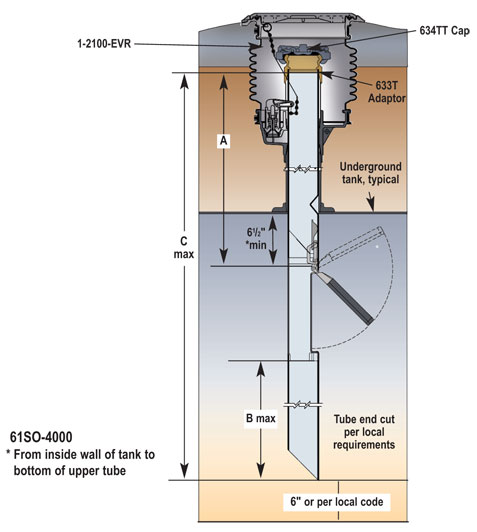

61SOR Remote-Fill and Two-Point Fill Applications

Replacement Parts

| Product # | Description |

| 61SOK-0001 | Float Kit |

| C03899M | Two-Point Inlet Tube |

| C03632M | Coaxial Inlet Tube |

| D01756 | Inlet Tube/Adaptor Assy. for 61SOP |

| H11931M | Drop Tube O-Ring |

| C03749 | Trap Door Assy. (Remote) |

61SOK Float Kit Instruction Sheet order Number: H11403PA

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD CHF

CHF HKD

HKD JPY

JPY RUB

RUB BRL

BRL CLP

CLP NOK

NOK DKK

DKK SEK

SEK KRW

KRW ILS

ILS MXN

MXN CNY

CNY SAR

SAR SGD

SGD NZD

NZD ARS

ARS INR

INR COP

COP AED

AED